- sales@trusogroup.com

- +971 55 961 5439

- Abu Dhabi, UAE

PRODUCTS

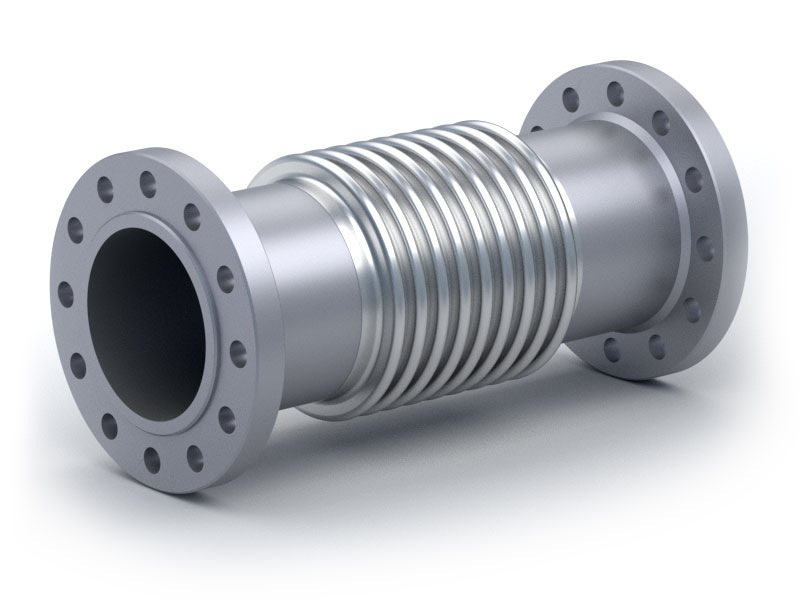

Expansion Joints

The most basic type of expansion joint is designed to absorb the various movements (axial, lateral, and angular) of the pipe section it is installed in. It can accommodate these movements by utilizing a single metal bellows element, which can be equipped with fixed flanges, floating flanges, or pipe weld ends. To promote smooth flow and minimize friction losses, internal flow liners can be installed.

It’s important to note that these metal expansion joints do not counteract the internal pressure thrust. Therefore, the piping designer must incorporate separate anchoring and guiding mechanisms in the system to resist the pressure thrust.